O'ring Slot Design

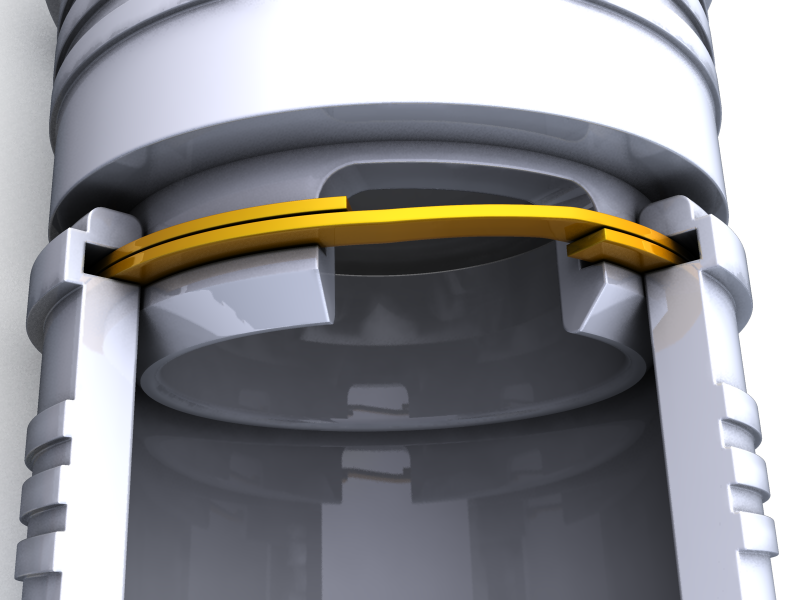

- DESIGN DIMENSIONS FOR O-RING INSTALLATION O-rings are normally used as seals in several ways, and dimensions of the groove or gland will also vary with the cross section of the ring, the type of operation, and the amount of pressure used in the system. These dimensions will also be different if the O-ring is sealing a liquid which has a low volume.

- Slot Hole Design Consideration: Slotted holes are widely used in most sorts of mechanical design. Apply mainly in precisely fine-tuning for uncontrollable dimensions beforehand, alignment accuracy, fixation in certain direction meanwhile keeping slipping free in other directions, and so on.

O-ring Groove Design Parker

O-Rings are the most widely used seal for they offer an efficient and economical sealing element for a wide range of static or dynamic applications and are easy to use due to their inexpensive production methods. Slot car chassis and chassis kit products available at Professor Motor, Inc.

O-ring groove design is a key consideration in the o-ring selection process. Browse design considerations and recommendations for static face seals, metric o-rings, static dovetail o-rings, static rod-piston o-rings and dynamic rod-piston o-rings. Once you find the right o-ring groove design you can easily order online from the world's largest o-ring inventory network.

| Chart | ||

|---|---|---|

| O-Ring Gland Design Considerations | View Online | Download PDF |

| Static O-Ring Groove Design Face Seal | View Online | Download PDF |

| Metric O-Ring Groove Design | View Online | |

| Static O-Ring Groove Design Dovetail | View Online | Download PDF |

| Static O-Ring Groove Design Rod-Piston | View Online | Download PDF |

| Dynamic O-Ring Groove Design Rod-Piston | View Online | Download PDF |

Can O-rings be used in rectangular or non-circular groove patterns? This question comes up weekly, and the answer is a resounding “Yes!” however there are definite guidelines we want to follow. A non-circular face seal footprint might also be called a racetrack groove, a wandering groove or a custom plan view. When using an O-ring, the main design consideration is the corner or smallest radius (shown “r” in diagram). The inside radius should be at least three times the O-ring cross sectional diameter. In a perfect world, six times greater is even better. What we want to avoid is over-stressing the O-ring around the bend, or causing a corner crease which increases likelihood of corner leakage. Designing the radius at six times the cross section will minimize the bending stress, resulting in increased service life.

Ideal design: r > 6 x W diameter but no less than r > 3 x W diameter

To minimize installation difficulties arising from stretch or OD compression on the seal, the centerline perimeter of the groove should match the centerline circumference of the O-ring. The rectangular cross section of the groove will follow the suggested guidelines in the O-Ring Handbook.

For those times when hardware real estate is at a premium and we simply cannot increase the inside corner radii to the desired size, an alternative option is the O-Seal. The O-Seal has a round cross section like an O-ring. However the footprint of the O-Seal is designed to match the shape of the groove. The primary advantage of the O-Seal is custom molding to fit the exact groove, eliminating the concern that comes with bending stress at the corners. A smaller corner radii can be used for the groove, allowing the footprint to fit perfectly within the application’s design constraints.

O Ring Groove Design Formula

If there are multiple ports or openings on the face, or bolt holes to contour around, these seals can be consolidated into a single O-seal solution. By consolidating seals, the installation process becomes much easier. All seals are ready to be installed at the same time, and the risk of installing the incorrect seal material is eliminated. This may offer the added advantage of streamlining the bill of materials and simplifying the amount of stock to be replenished during the assembly process.

O-Seals are available in nearly every material family and engineered for optimum size and configuration for each unique application. Parker Application Engineers are happy to assist you with your racetrack groove design or a custom O-Seal. Please contact us today via online chat or by email by visiting Parker O-Ring and Engineered Seals Division website.

This article was contributed by Dorothy Kern , applications engineer lead, O-Ring & Engineered Seals Division

O-ring Groove Design Trelleborg

Related content: